Within the multifaceted landscape of product development, a journey that navigates through the intricacies of transforming conceptual ideas into market-ready realities involves many meticulous steps. Standing as an indispensable linchpin in this intricate process is the pivotal discipline of material testing. A material testing laboratory dedicated to thoroughly examining the properties and characteristics of diverse materials emerges as the guardian of integrity in the intricate manufacturing world.

These specialized laboratories play a central role in ensuring the quality and reliability of products, meticulously scrutinizing the very foundation of materials. In the dynamic interplay of innovation and practicality within manufacturing, Material Testing Laboratories stand as vanguards, expertly examining materials to meet and surpass industry standards, contributing significantly to creating high-quality and dependable products.

This blog post delves into the crucial significance of an A material testing laboratory and its impact on developing high-quality and reliable products.

Why Material Testing Matters: A Foundation for Quality Assurance

Identifying Material Properties:

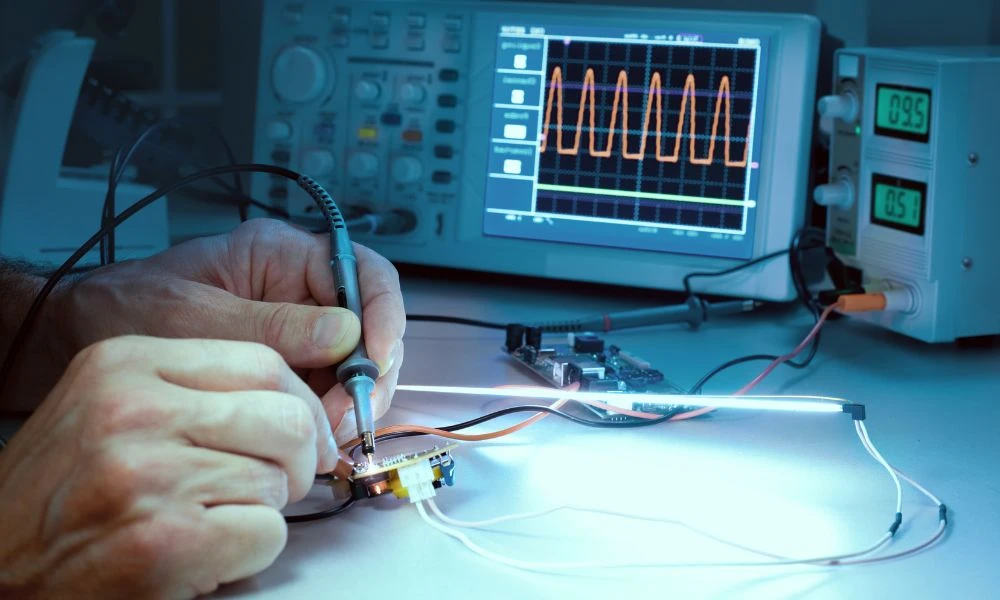

A material testing laboratory boasts a sophisticated arsenal of cutting-edge techniques and specialized tools meticulously designed to delve into the intricate nuances of diverse materials. Be it metals, polymers, ceramics, or composite materials, these laboratories utilize state-of-the-art methods to scrutinize fundamental properties critical to the overall performance and reliability of end products.

The examination extends to critical characteristics such as tensile strength, hardness, elasticity, and beyond, offering an exhaustive understanding of how materials behave under various conditions. This wealth of knowledge serves as the bedrock for the meticulous process of material selection, providing engineers and manufacturers with invaluable insights to pinpoint the most suitable materials tailored to the specific demands of a given product application.

In essence, the advanced capabilities of material testing laboratories allow for a comprehensive analysis of materials and empower decision-makers to make informed choices that directly impact the quality and durability of the final product.

Quality Control at Every Stage:

Within the intricate process of product development, quality assurance is not a singular event but an ongoing commitment. A Material testing laboratory is pivotal in facilitating this continuous vigilance at every stage of the production journey.

Commencing with the thorough inspection of raw materials, extending through the assessment of prototypes, and culminating in scrutinizing the final production output, these specialized laboratories are instrumental in ensuring that materials adhere to predefined standards.

This systematic and thorough approach serves as a robust defense against potential defects and malfunctions, minimizing the risk of imperfections that could compromise the integrity and reliability of the end product.

By integrating quality control seamlessly into each stage of the development process, material testing laboratories contribute significantly to the creation of products that not only meet but exceed the stringent standards outlined in the industry.

Mitigating Risks and Ensuring Safety:

Material failures, particularly in high-stakes industries such as aerospace, automotive, and healthcare, can unleash catastrophic consequences with far-reaching implications. Recognizing the gravity of such scenarios, material testing laboratories adopt a proactive stance by conducting rigorous tests designed to identify potential material weaknesses.

This meticulous scrutiny is paramount in ensuring that the final products meet and surpass the stringent safety standards and regulations set forth by governing bodies. By embracing a comprehensive and systematic testing approach, these laboratories play a crucial role in mitigating the inherent risks associated with product failure.

This commitment to proactive testing not only safeguards the reputation of industries but, more importantly, ensures the well-being and safety of end-users, reinforcing the pivotal role of material testing in maintaining the highest standards of quality and reliability in critical sectors.

Check out our blog on Material Testing in the automotive industry to better understand this section.

Crucial Roles of A Material Testing Laboratory:

Innovation and Research:

Material testing labs contribute significantly to innovation and research. Researchers push the boundaries of what is possible by experimenting with new materials and testing their limits. This exploration is critical for industries developing cutting-edge products with enhanced performance and durability.

Customization and Optimization:

Different products demand different material properties. A material testing laboratory enables customization by tailoring materials to meet specific requirements. Whether it’s developing lightweight materials for automotive applications or corrosion-resistant alloys for marine use, customization is vital in optimizing product performance.

The Economic Impact:

Cost Reduction Through Failure Prevention:

A Material Testing Laboratory is crucial in averting catastrophic financial consequences resulting from product failures. By adopting a proactive approach, these specialized labs identify potential issues early in development, preventing malfunctions or defects.

This early scrutiny significantly diminishes the likelihood of product recalls, warranty claims, and the associated financial burdens. Material Testing Laboratories are a strategic investment for industries, safeguarding financial resources and preserving brand integrity and reputation.

This proactive stance allows companies to allocate resources efficiently, focusing on innovation and improvement rather than addressing costly mistakes after a product has entered the market.

Enhanced Product Lifecycle:

Products subjected to rigorous material testing often exhibit an extended lifecycle, a testament to the profound impact of systematic testing procedures. The insights gained from comprehensive testing empower engineers with a nuanced understanding of how materials will behave over time in real-world conditions.

This in-depth knowledge bolsters the product’s reliability and contributes significantly to its sustainability. By designing products with a keen awareness of material behavior, engineers can implement measures to enhance durability, reduce wear and tear, and minimize the environmental impact throughout the product’s lifecycle.

The synergy between material testing and product design ensures longevity and reliability. It fosters a commitment to sustainable practices, aligning with the growing emphasis on environmentally conscious and responsible manufacturing.

You are now well-versed in the fundamentals of the material testing laboratory and its functions. Try SMS LAB’s material testing services for better results for your business.

Conclusion

A Material testing laboratory stands as an unsung hero in the intricate dance of product development. Their meticulous work ensures that the materials chosen are suitable and optimal for the intended application. From preventing catastrophic failures to enhancing innovation, the importance of material testing in product development cannot be overstated.

As industries continue to evolve, the role of A material testing laboratory will remain central to the quest for ever-improving quality and reliability in the products we use every day.